Mine Site Dredging

CLICK HERE TO LEARN MORE!

We offer speciality dredging equipment designed to desilt and desludge a range of slime ponds, tailings lagoons and contained waterways at mine sites.

Dredging solution provider to the mining industry undertaking dredging of mine ponds, mine lagoons, tailings dams, mine sludge or industrial dewatering projects.

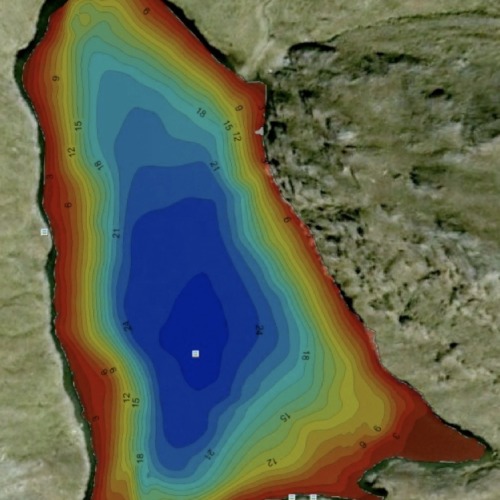

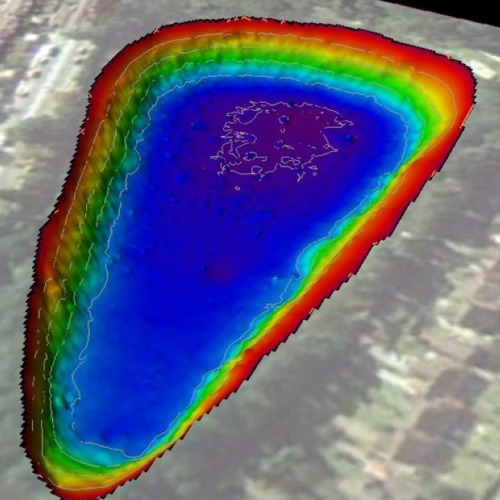

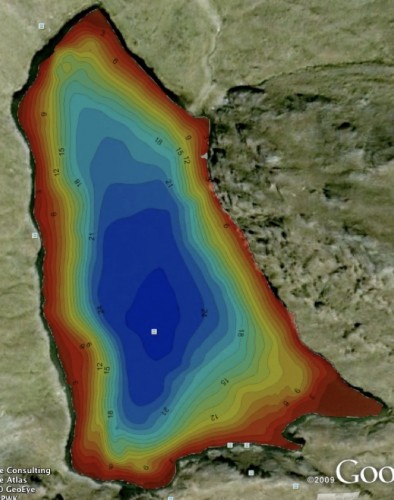

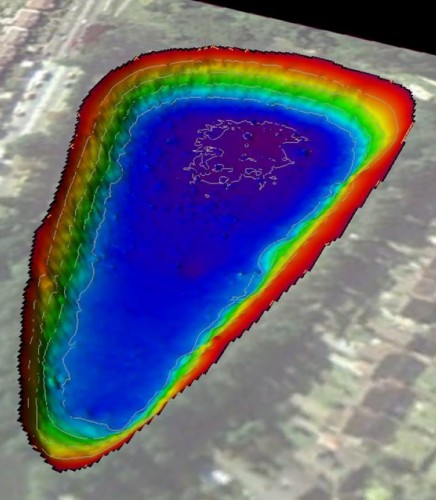

We can undertake surveys of tailings dams and lagoons to determine the topography of the dam floor (ie. dam profile) and estimate the amount and position of the solids to be removed.

About Us

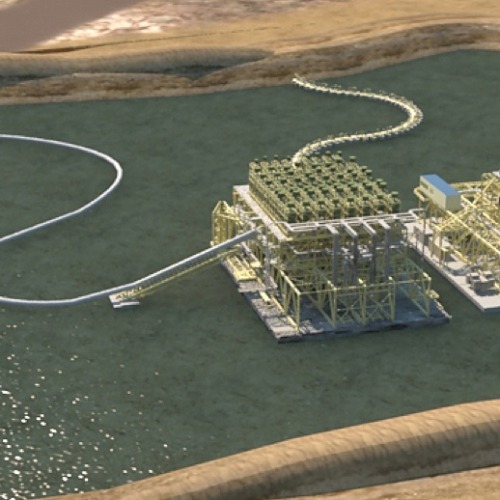

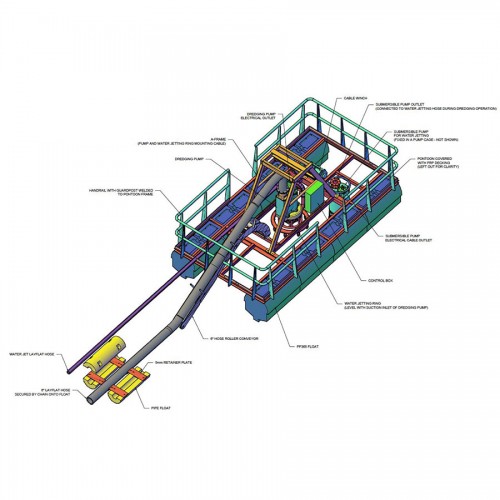

We operate a fleet of compact cutter suction dredgers and sub dredgers supported by an extensive array of ancillary equipment including pontoons, booster pumps, work barges, pipefloats and pipelines.

Mine Dredging Services has the capabilities and engineering know-how to handle challenging dredging projects around Australia.

Mine Dredging Services use custom-built dredgers for dredging Sand, Mud, Tailings, Slimes, Slurries, Mineral Sands, Mineral Concentrates and Gravels

Our floating dredgers are highly mobile and is easily transported by truck to anywhere in Australia.

How We Can Help

Mine Dredging Services operate two dredge models for small to medium dredging operations. These units are readily road transportable with standard road transport.

Our mini dredgers can be used on sites with tight or restricted access.

Our portable dewatering systems enable us to pump sand slurries of up to 40% and dewater them effectively through either hydrocyclones or geotextile filter bags.

Mine Dredging Services offers Dredges, Dredging, Dredging Contractors, Environmental Dredgers and also Dredging Equipment.

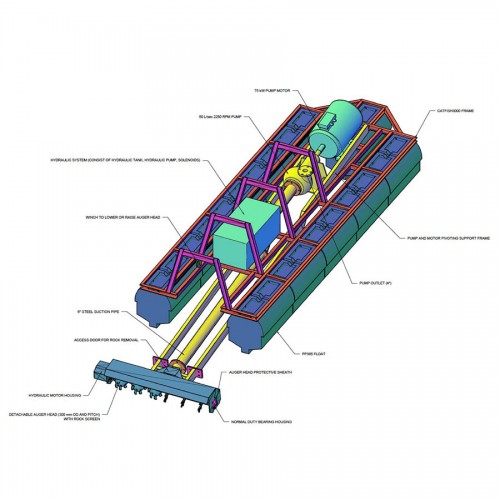

We also have a range of specialised dredging, pumping and ancillary equipment available. Our dredging technology, include cutter auger fronted units and sub-dredge options.

The dredgers can be fitted with liner protection systems so they can be used for the safe dredging of HDPE geomembrane lined ponds without risking damage or rupture of the polyethylene liner.

Our Mine Dredging Equipment

Our equipment consists of two different types of dredgers: the Catfish™ Cutter Suction Dredge and the Catfish™ Submersible Suction Dredge. Both dredge types are very capable and can efficiently dewater, desilt and desludge mine ponds and lagoons to restore them to their original capacity. These mini dredgers can remove sand, silt, sludge and coal fines from mine process dams, evaporation ponds, tailings dam or process water lagoons and discharge these materials over 300 metres through our proprietary UltraPE™ pipelines. Maintenance dredging is an important function at mine sites to ensure process ponds or retention lagoons have sufficient holding capacity.

Catfish cutter suction dredgers are the perfect choice for mining and dredging aggregate materials from depths of 1 m to 3.5 m.

Catfish submersible dredgers are the perfect choice for mining and dredging aggregate materials from depths of 1 m to 15 m.

Mine Sand Dredging

Our dredgers are equipped with high capacity, rubber-lined slurry pumps that can handle high concentration of abrasive sand slurries such as beach sand, mineral sands and sand tailings.

Mine Dam Surveys

Mine Dredging Services can undertake surveys of tailings dams and lagoons to determine the topography of the dam floor (i.e. dam profile) and estimate the amount and position of the solids to be removed. Surveys are conducted using a remote controlled survey craft equipped with both sonar and GPS. As the craft is controlled from the shore there are no issues with OH&S.

UHMWPE Pipelines

We use special abrasion resistant dredging pipes based crosslinked polyethylene (PEX) or ultra high molecular weight (UHMWPE) polyethylene

These pipes are lightweight, quickly assembled on site using flared flanges and capable of discharging a wide range of materials over long distances including sand, minerals and coal fines.